Back in 2003, Clayton glass was a much smaller company. We were operating out of a smaller factory, despatching fewer products to less customers. Around the time, we were experimenting with our Double-Glazed units, by filling them with Argon gas…

The theory was, because Argon gas is denser than air, that it should therefore improve the thermal insulating properties of a glass unit. Excitingly, This theory turned out to be on the money.

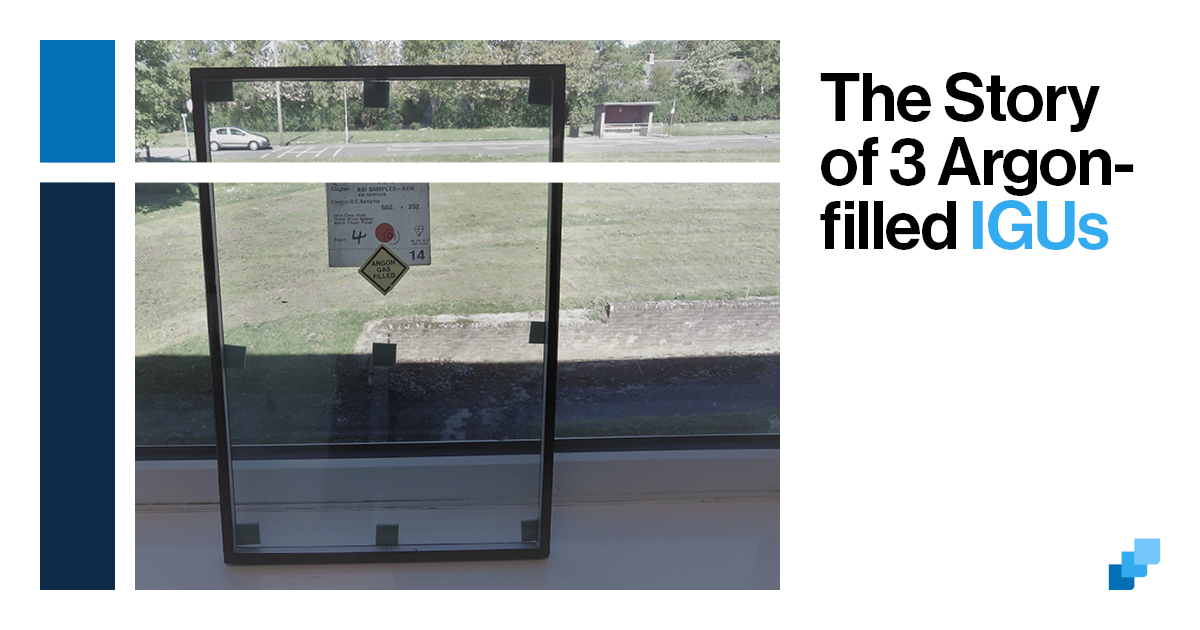

In 2003, we produced three, experimental, Argon gas filled sample units, to test the theory that Argon gas insulated better than air. In 2003, These three Double-Glazed units were filled with Argon gas concentrations of 91.50, 92.30 and 93.20.

Fast-forward to 2019. Clayton Glass has now become one of the largest manufacturers of insulating glass units in the United Kingdom. Now operating out of a state-of-the-art factory with over 100 customers and clients, and many more staff. We now despatch over 4,000 products a week and process over 75,000 tonnes of glass, every year.

However, we have not forgotten where we came from. These Argon gas filled sample units, created in 2003, now contain Argon gas concentrations of 86.35, 86.55 and 89.20 respectively.

Each unit contains at least 93.7% of the Argon gas it was originally filled with 16 years ago.

At Clayton Glass we build our glass units to last, we always have, and we always will.

That’s #TheClaytonDifference